Timing Belt

- Accurate transmission

- Smooth transmission

- High transmission efficiency

- Wide speed ratio range

Industrial rubber synchronous belt, also known as synchronous belt, is a circular transmission belt with a cross-section of rectangular or approximately rectangular, and an inner surface (or inner and outer surfaces) with equidistant transverse teeth. Industrial rubber synchronous belt is a ring-shaped belt made of steel wire rope or glass fiber as a strong layer, covered with polyurethane or chloroprene rubber. The inner circumference of the belt is made into a toothed shape, which meshes with the toothed belt wheel. When the industrial synchronous belt is driven, the transmission ratio is accurate, the force on the shaft is small, the structure is compact, the oil resistance is good, the wear resistance is good, and the anti-aging performance is good. The general use temperature is -20 ℃ -80 ℃, v 50 m/s, P 300kw, i 10. For the transmission that requires synchronization, it can also be used for low-speed transmission. Industrial rubber synchronous belt transmission is composed of a circular belt with equidistant tooth shapes on the inner surface and corresponding matching wheels. It combines the advantages of belt drive, chain drive, and gear drive. When rotating, power is transmitted by meshing the teeth with the grooves of the wheel. Industrial rubber synchronous belt transmission has accurate transmission ratio, no slip, can achieve a constant speed ratio, smooth transmission, can absorb vibration, low noise, and a large transmission ratio range, generally up to 1:10. Allowing a linear speed of up to 50M/S and transmitting power from a few watts to a hundred kilowatts. High transmission efficiency, generally up to 98%, compact structure, suitable for multi axis transmission, no lubrication, no pollution, so it can work normally in places where pollution is not allowed and the working environment is relatively harsh. Transmission products are widely used in various types of mechanical transmissions in industries such as textiles, machine tools, tobacco, communication cables, light industry, chemical industry, metallurgy, instrumentation, food, mining, petroleum, and automobiles.

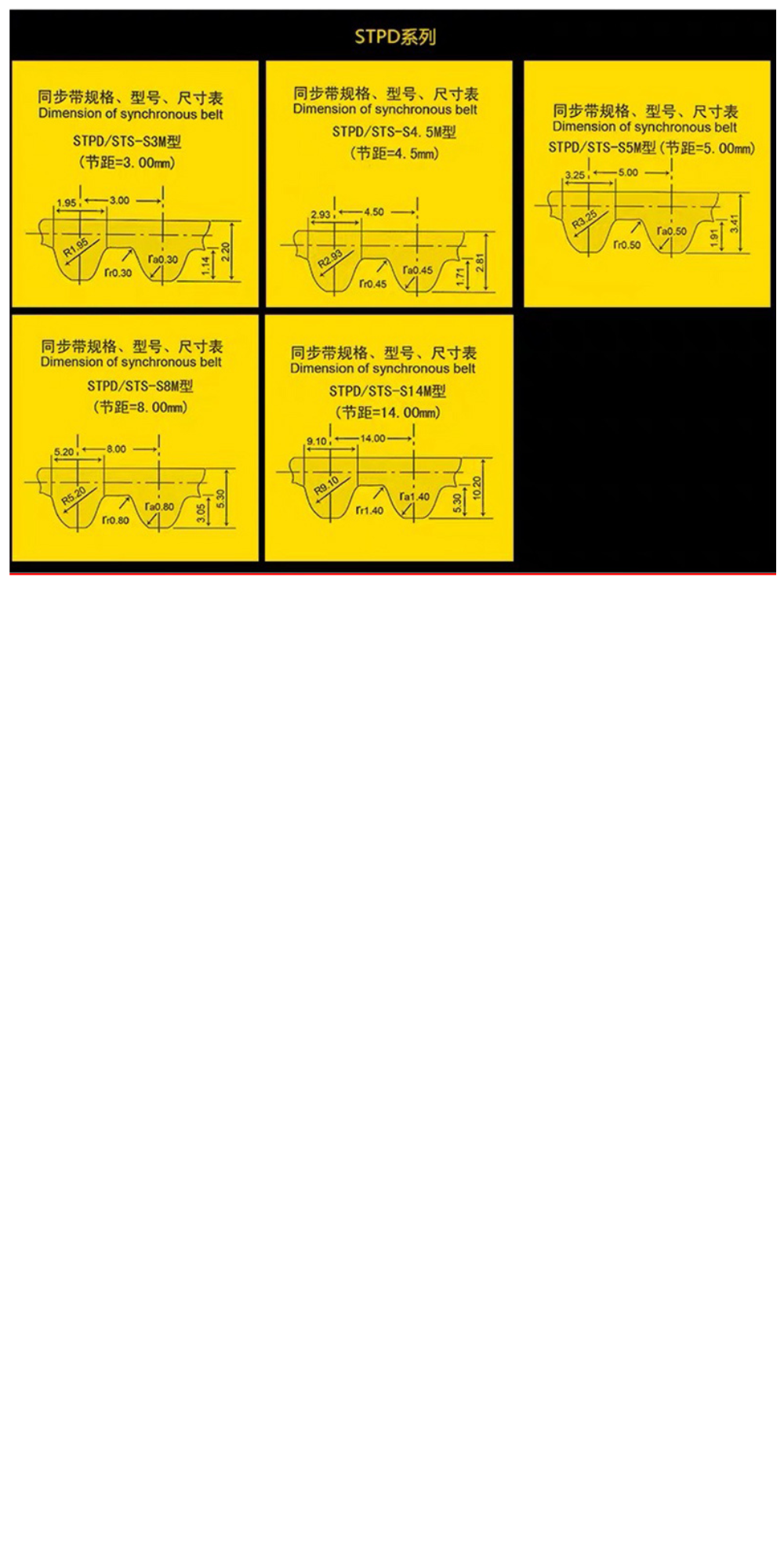

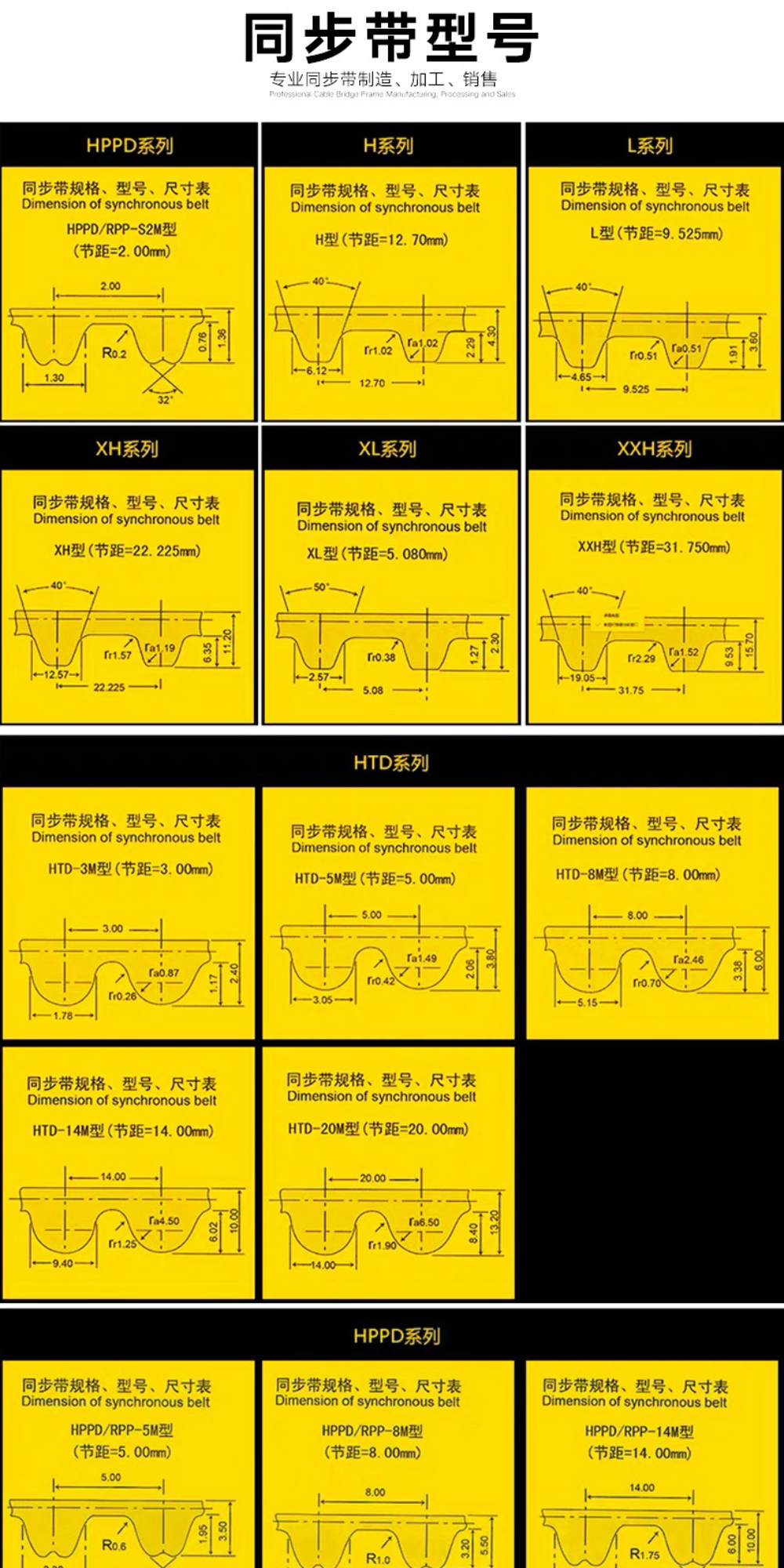

Tooth profile diagram of industrial rubber synchronous belt

Industrial rubber synchronous belt representation method

What are the advantages of industrial rubber synchronization?

A. Accurate transmission, no sliding during operation, with a constant transmission ratio;

B. Smooth transmission, with buffering and vibration reduction capabilities, and low noise;

C. High transmission efficiency, up to 0.98, with significant energy-saving effect; D. Convenient maintenance, no need for lubrication, and low maintenance costs;

E. The speed ratio range is large, usually up to 10, and the linear speed can reach 50m/s, with a large power transmission range of several watts to several hundred kilowatts;

F. Can be used for long-distance transmission, with a center distance of over 10m.

What are the precautions for installing and using industrial rubber synchronous belts?

The synchronous belt must not be twisted during storage, otherwise it may cause the tensile layer to break. The minimum allowable bending diameter is shown in the table below. The types and models of synchronous belts allow for the minimum bending diameter of trapezoidal toothed synchronous belts MXL, T2.5 15 XL, T5 15 L, AT5, T10 20 AT10, H 40 XH, T20 70 XXH, 20M 100 arc toothed synchronous belts S2M, S3M, 3MRPP2M, RPP3M 15 S4.5M, S5M, 4M, RPP5M 25 S8M, 8M, RPP8M 40 S14M, 14MRPP14M 80. The synchronous belts must not be stored in an abnormal bending state for a long time.

1. Please store in a cool place.

2. Please shorten the center distance or loosen the tensioning wheel during installation, and then reset it. Do not forcefully pull, drag, or grind the synchronous belt onto the edge of the wheel.

3. The edge line of the synchronous belt must be perpendicular to the tooth surface of the wheel during installation.

4. The parallelism of the main axis between the driving wheel and the passive wheel should be controlled at around tangent tg=1/1000. The axis position will not directly affect the service life.

5. If the phenomenon of belt running edge is found, the parallelism of the two axes or the axial position of the two wheels should be adjusted. And adjust the pressure of the tensioning wheel.

6. If any looseness or tooth jumping is found in the synchronous belt, it is necessary to immediately check whether the center distance is correct or loose and shifted. Otherwise, it should be adjusted or reinforced.

7. When installing the synchronous belt, the tension must be adjusted appropriately according to different specifications, models, and bandwidths.

8. The tensioning wheel must be installed on the loose side during synchronous belt transmission.