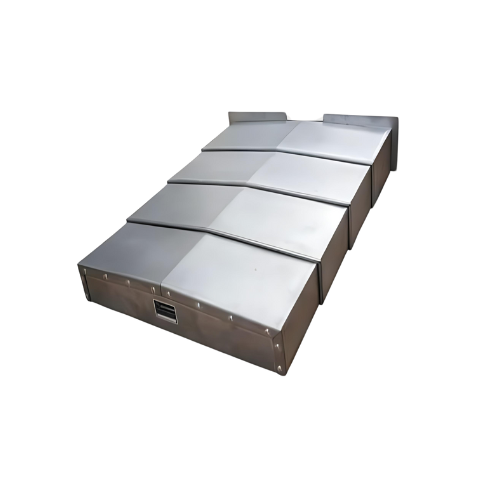

Steel Plate Protective Cover

- Good sealing performance

- Smooth expansion and contraction

- Sturdy structure

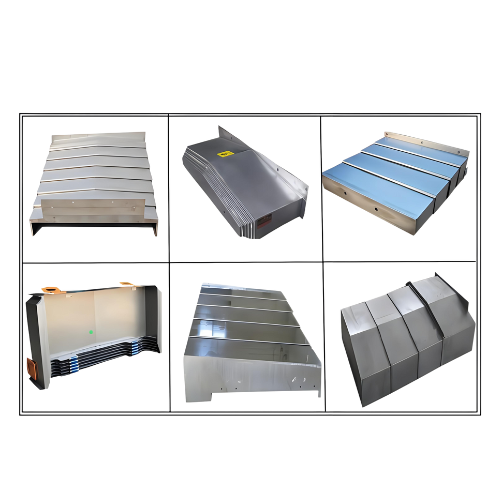

The machine tool protective cover is used to protect the machine tool guide rails. It can protect the internal hard guide rails, linear guide rails, ball screws or transmission racks of the machine tool from external corrosion and damage. There are many types of them, including: organ protective covers, steel plate protective covers, which are used on guide rails; The protective covers used on the screw also include: circular, square, polygonal, which have different methods, including steel wire support and stitching. There are also roller blind protective covers and armor protective covers, etc.

Machine tool protective cover is a product specifically designed to protect the machine tool bed and guide screw.

It can be divided into: steel plate protective cover, organ protective cover screw protective cover, armor type protective cover, rolling shutter protective cover, etc.

So when purchasing products, buyers must consider which type of machine tool is suitable for them before purchasing!

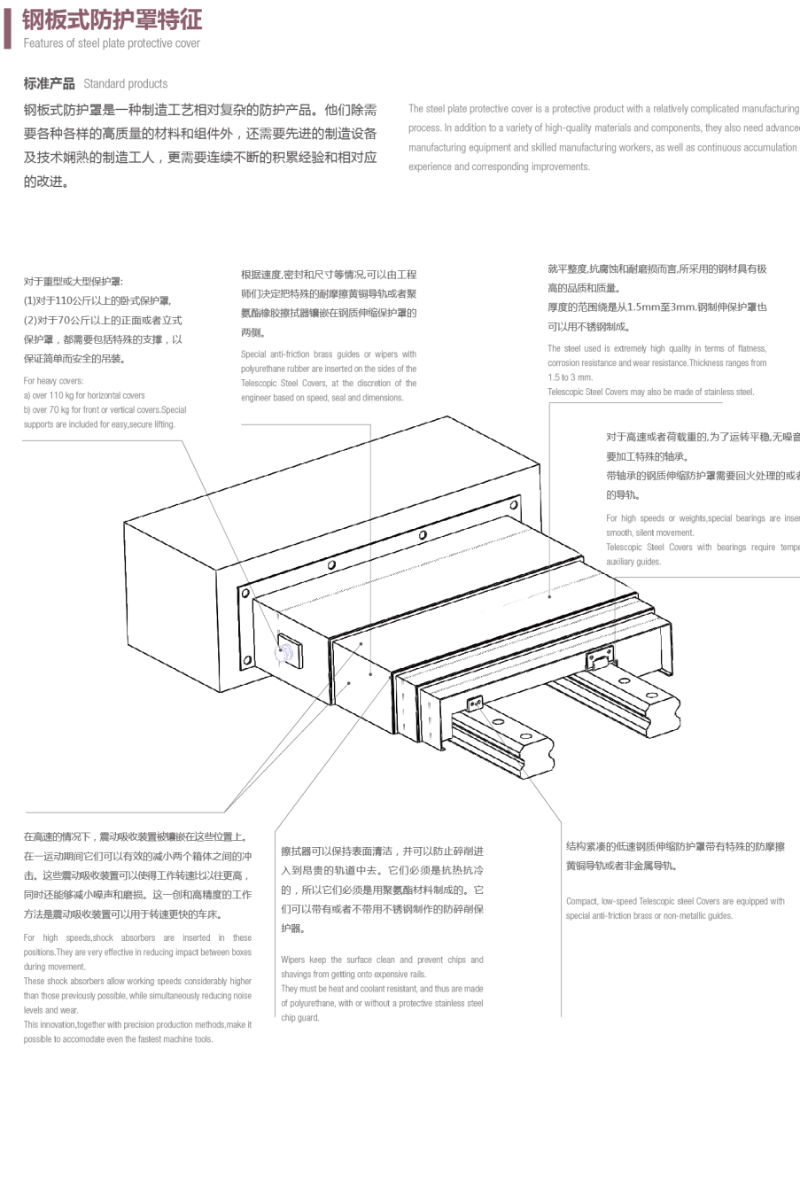

The steel telescopic guide rail protective cover is a traditional form of protection for machine tools. In this field, steel telescopic guide rail protective covers are widely used, playing an effective protective role in preventing the entry of chips and other sharp objects. Through certain structural measures and suitable scraper plates, the infiltration of coolant can also be effectively reduced. Our steel telescopic guide rail protective cover can meet the constantly improving requirements of modern machine tools for high-tech, correct installation position, high operating speed, and other aspects.

technical data

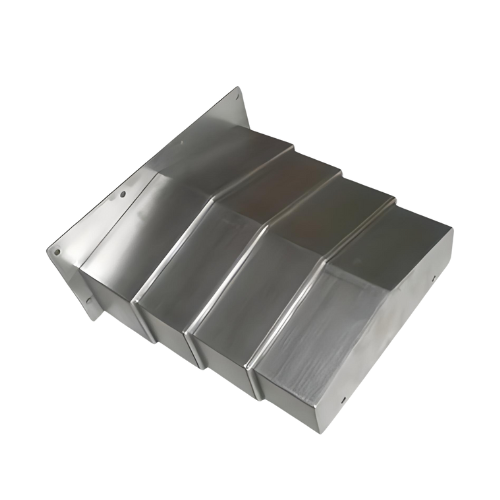

The steel telescopic guide rail protective cover is made of high-quality 2-3mm thick steel plate cold-formed, and can also be made of stainless steel according to requirements. Special surface polishing will cause it to appreciate in value. We can provide corresponding rail protection types (horizontal, vertical, inclined, lateral) for all types of machine tools.

The protective cover structure we develop varies depending on the operating speed and guide rail. We are equipped with polyurethane or brass sliders for speeds below 10m/min. We are equipped with rollers at a moderate speed of 30m/min. In addition, a buffer system is required between the driver board, scraper board, and suction board. The purpose of the slider buffer system is to reduce collisions, noise, and friction.

The number of sections of the steel telescopic guide rail protective cover is important for its proportion, weight, and operating characteristics. Each single section should be as long as possible, which can reduce the number of sections and lower costs. In general, the maximum tension and minimum compression ratio should be between 3:1 and 5:1.

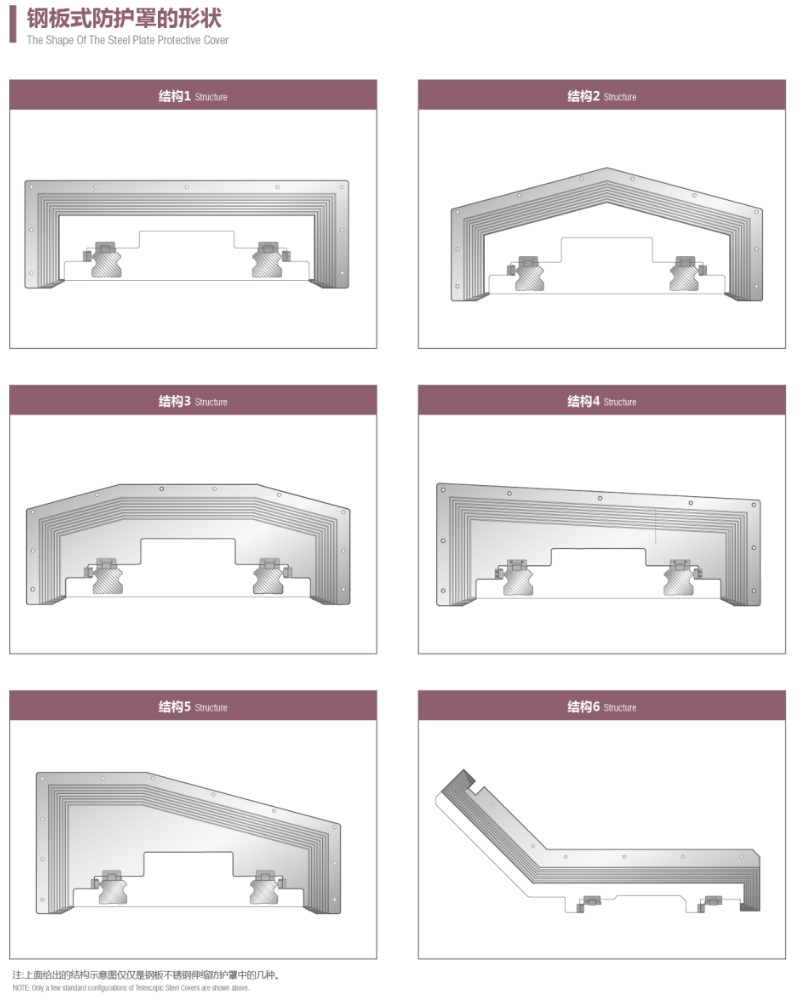

Structure: The steel plate type protective cover is mainly assembled from panels, support plates, sliding sheets or pulleys, hinge mechanism (optional according to operating speed), sealing strips, cushion rubber pads and other components.

Features: The fit between each section of the steel plate type protective cover is. relatively close, and daes not affect the running speed, and can more effectively protect against dust, iron filings, and cooling liquid. Its quality is excellent. Long life,beautiful appearance, and can be stepped on without deformation when applied to machine tools.