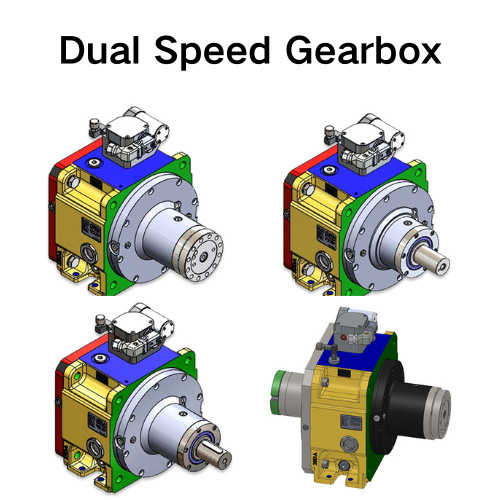

Double Speed Gearbox

- Low back clearance

- Low vibration value

- Low temperature rise

Two-speed gearbox is mainly used for the spindle of tool machine, test bench and processing application requiring high torque.

Through precise reduction device and high efficiency transmission, the motor input speed is reduced or continued to meet the processing requirements and reduce energy consumption. Two-stage variable speed mechanism can increase the output speed range, improve the machining flexibility and machining accuracy of tools, and effectively extend the power output of motor and increase the machining torque: the increase of output speed range represents a wider range of work-piece materials that can be machined. For example, low output speed and high torque output can process hard materials or improve the removal rate, improve the machining efficiency of tools, process soft materials at high output speed or improve the surface machining quality of work-piece. The design structure of spiral planetary gear set is compact, providing higher transmission efficiency, optimal noise value and smaller volume than straight gear box. With modular combination, it can be easily matched with main brand spindle motors through different connecting end plate sizes.

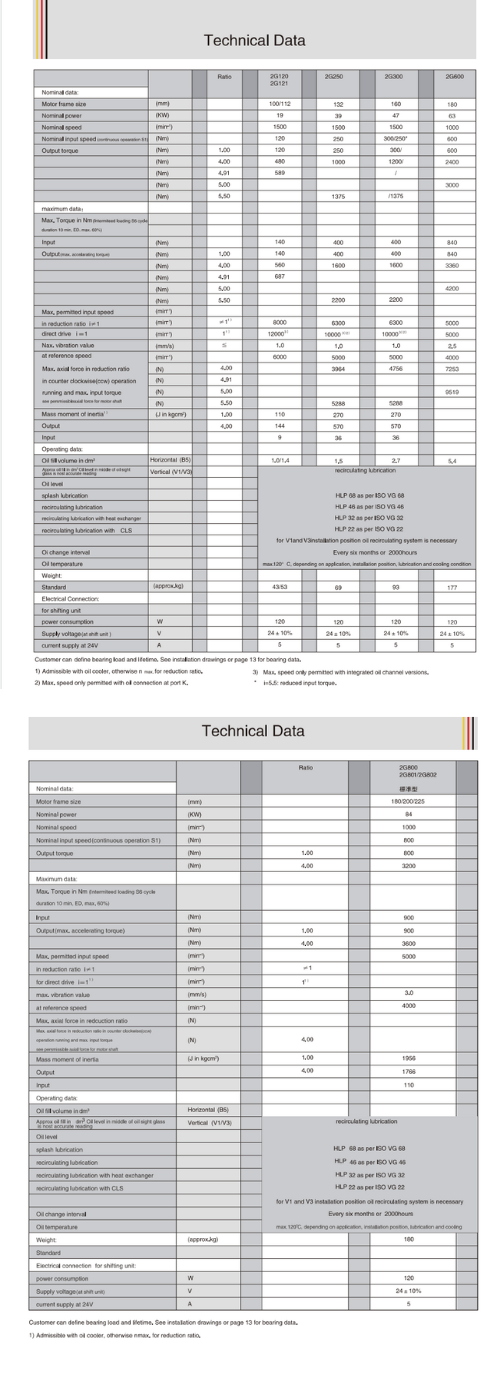

Speed ranges 1:4/1:5.5 are availat le, constant power of main spindle can be achieved with the gearbox, depending on the controllable range of motor. Th is provides high torque at low speed on the one hand and high power at high speed on the other, allowing the cu tting power of modern tools to be fully utilized.

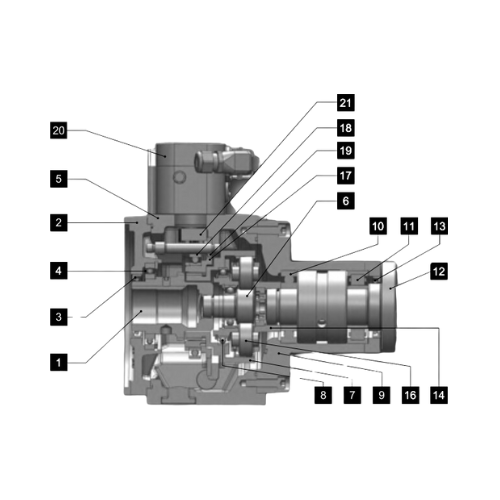

GTP-2G is an innovative two speed gear box for machine tools, characterized by extremely low noise and vibration as well as excellent shifting mechanism. German Engineering!GTP-2G is designed and developed by GTP's R&D center located in Germany based on state of the art technology and abundant experience in machine tool industry.

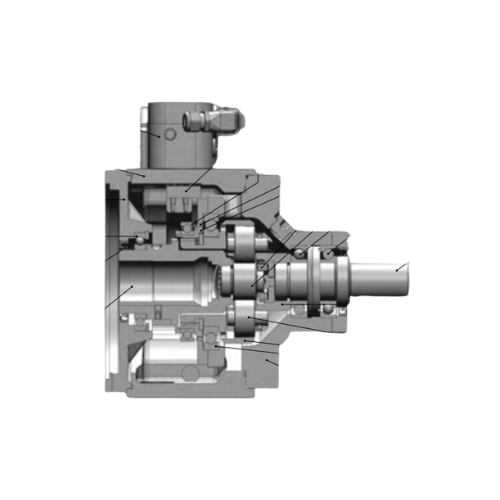

GTP-2G adopts single stage planetary gear concept with two speed shifting mechanism in order to meet various demands from worldwide machine tool industries.

In contrast to conventional spur gearboxes, this planetary gearboxcaptivates by benefits of the division of power to 4 planetary gears, thus achieving a extremely compact and space saving design.

In Addition, the four simultaneously meshing helical planetary gears assure low-noise operation at high speed.

Misalignments and concentricity issues are ideally concentrated by the floating design of the sun gear. Thus such a planetary gearbox is much less sensitive to tolerance.

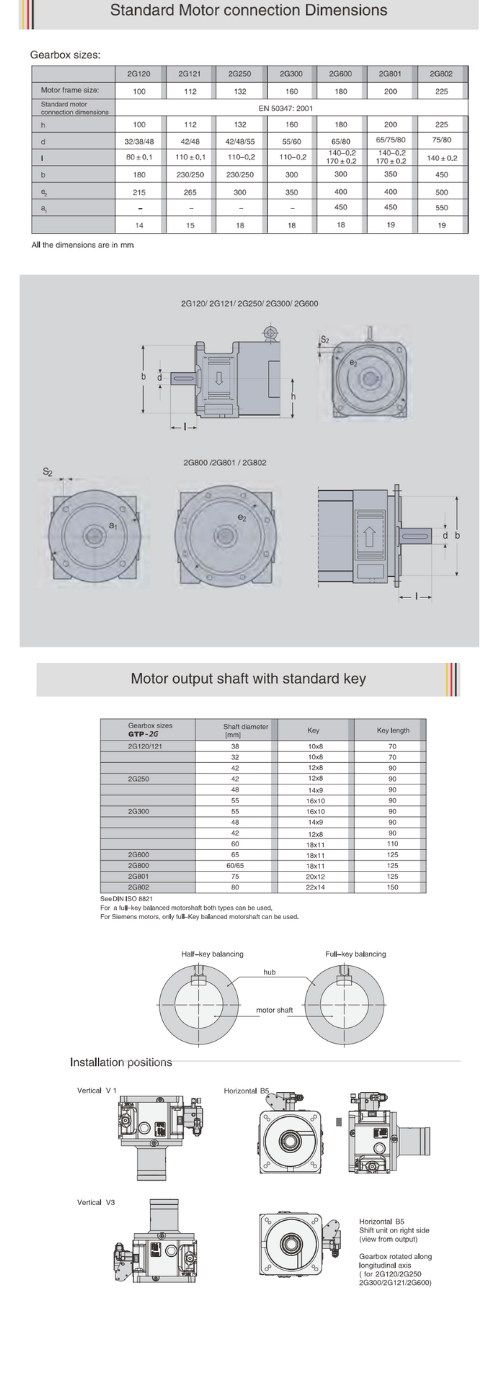

The motor-gearbox unit is commonly fixed to the machine frame or bed by using the gearbox foot mount(Available for2G120,2G250,2G300,2G600 only).

Each gearbox has available an output side pilot for flange mounts. For each application there is an ideal choice of output bearing with a wide bearing base.

Variable output housings suitable for different main spindle design: e.g.GTP-2G STANDARD with wide bearing base for belt drives allowing high radial load.GTP-2G INLINE with short output housing and angular contact bearings for direct drive.