Spiral Chip Conveyor

- Compact

- Easy to install and use

- Extremely low failure rate

Spiral chip conveyor is an equipment used for conveying granular, powder, block, and roll shaped chips cut from metal and non-metal materials during mechanical processing

Spiral chip conveyor is mainly used for conveying granular, powder, block, and roll shaped chips cut from metal and non-metal materials during mechanical processing.

Can be used in CNC lathes, machining centers, or other places where the placement space of machine tools is relatively narrow. When used in conjunction with other chip removal devices, it can form different types of chip removal systems.

Spiral chip conveyor is divided into two types: cored and coreless. It is generally used in conjunction with other types of chip conveyor to transport iron chips collected from protective covers or workbenches to the chip inlet of the chip conveyor, and then transported to the collection vehicle by the chip conveyor. The spiral chip conveyor can also be equipped with a horn to directly discharge waste chips from the horn mouth onto the chip collection truck.

The spiral chip conveyor is easy to install, reliable in operation, and can advance at a speed according to user requirements. It is generally divided into three types

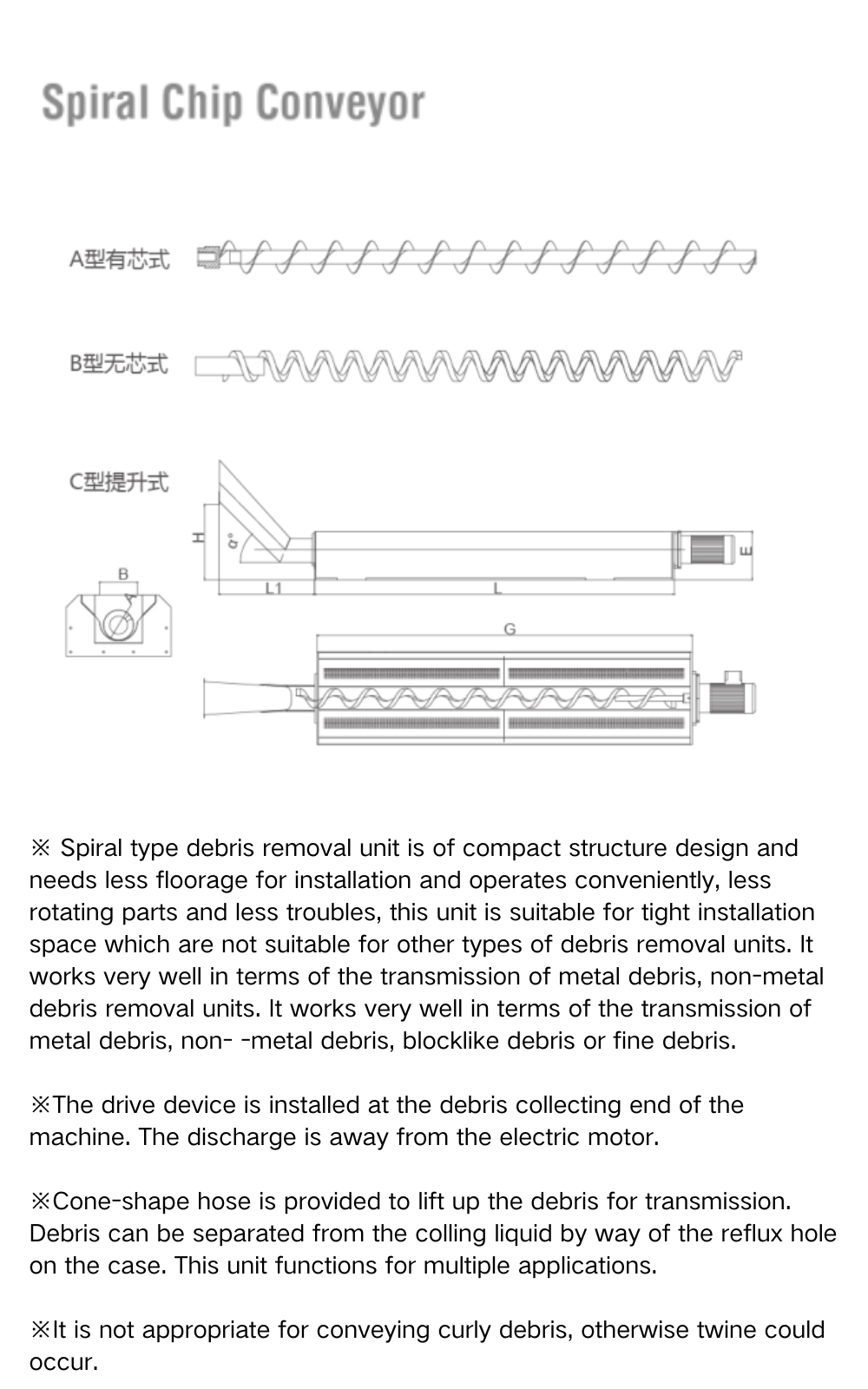

Type A: With core propulsion and conveying groove; Type B: With core propulsion and no conveying groove; Type C: Coreless propulsion (≤ 3000mm)

Instructions for use

Broadcast

edit

(1) Before starting up, the machine tool should be thoroughly and meticulously inspected to ensure accuracy before operation.

(2) After the machine tool is powered on, check whether all switches, buttons, and buttons are normal and flexible, and whether the machine tool has any abnormal phenomena.

(3) Check if the voltage and oil pressure are normal. For areas with manual lubrication, manual lubrication should be performed first

※Spiral type debris removal unit is of compact structure design and needs less floorage for installation and operates conveniently, less rotating parts and less troubles, this unit is suitable for tight installation space which are not suitable for other types of debris removal units. It works very well in terms of the transmission of metal debris,non-metal debris removal units. It works very well in terms of the transmission of metal debris, non--metal debris, blocklike debris or fine debris.

※The drive device is installed at the debris collecting end of the machine. The discharge is away from the electric motor.

※Cone-shape hose is provided to lift up the debris for transmission. Debris can be separated from the colling liquid by way of the reflux hole on the case.This unit functions for multiple applications.

※ It is not appropriate for conveying curly debris, otherwise twine could occur.